Foam Glass Construction Material - Foam Glass Gravel

Blaine Kennedy - Director

Foam Glass Materials Production and Applications

66 Caroline Avenue, Ottawa, On, Canada K1L 0S7

(613) 748-5213

(613) 295-9635

br.kennedy@geoglassgravel.ca

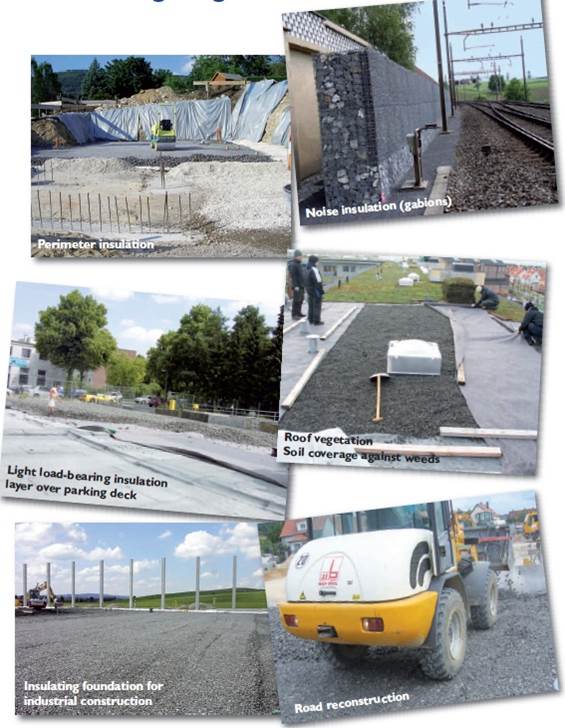

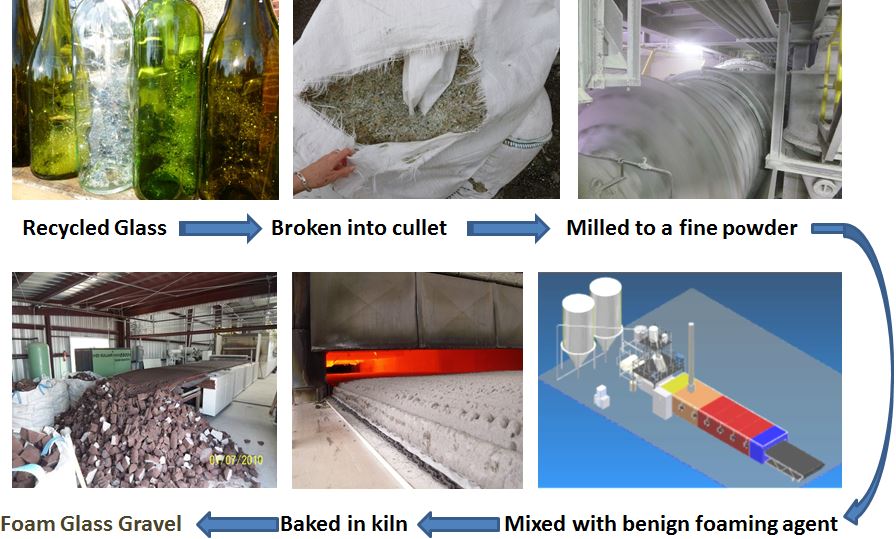

- GeoGlass foam glass gravel is a lightweight, structural, insulating material made from waste glass for special uses in infrastructure and building construction. Used for 25 years in Europe.

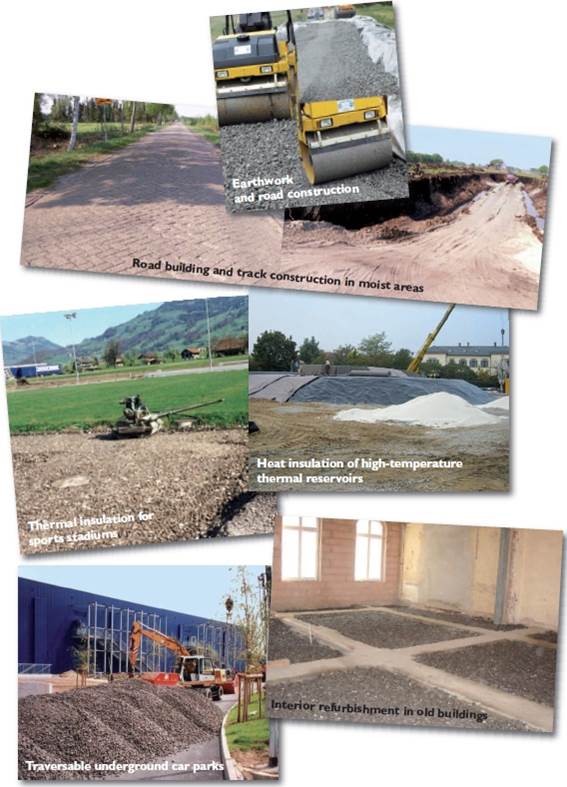

- Foam glass gravel is used to build roads and other infrastructure over soft terrain such as muskeg, swamps, peat bogs, silt, clay or wet soil. In cold climate with frost heaves, foam glass gravel is used for road and railroad construction, bridge abutments, retaining walls, culverts and as insulating cover over utility and energy pipelines.

- Foam glass gravel is used to insulate floors of buildings, as below grade perimeter insulation, on green roofs and many other types of building construction.

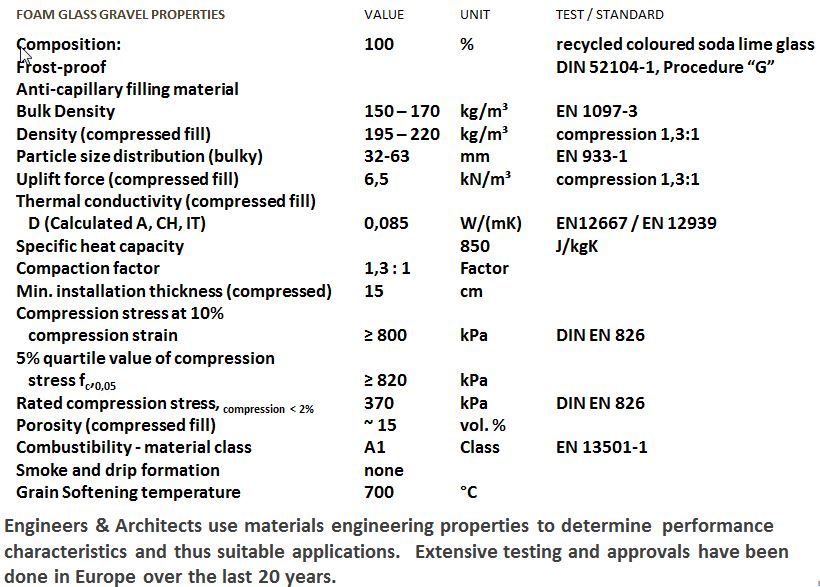

Foam Glass Gravel Characteristics

- Closed cell, tiny glass bubbles are non absorptive with no capillary action and superior draining rate.

- Very light weight (130 – 220 kg/m^3)

-

- Greatly reduces static load on soft ground.

- Easy to handle on site with dozers, long reach cranes and tote bags.

- Heat conductivity 0.08 – 0.09 W/mK.

- Installation costs less than rigid insulation and aggregate with a day time saving on a house.

- Compacts to level, solid base with good compressive strength.

Foam Glass Gravel Properties

FGG -- Advantages & Applications

High insulation value

Light weight – low density

High compressive strength

Relieves lateral pressure

High friction prevents creep

Superior hydraulic conductivity

Closed cell – minimal capillary action

Frost resistant

Sound absorbing

Non-conductive

Sustainable, low environmental impact

Low GHG embodied energy

Recycles waste glass

Chemically inert

Non-combustible

Rot proof, Pest proof

Airport EMAS

Below grade insulation for buildings

Insulated pipes – water, sewer, energy

Landscaping over roofs, garages, subways

Backfill structures – bridge abutments, retaining walls

Roads – soft terrain, permafrost

Easier to install, great value proposition to users

Foam Glass Gravel Materials Handling for Construction

Transport FGG in tote bags of by tractor trailer

On-site handling by cranes and bags, trailers, loaders or by hand tools

Infrastructure Uses

Proven uses in Europe:

- Light-weighting over soft terrain

- Road bed insulation to prevent frost heaves and protect permafrost

- Large culvert cover

- Back fill for bridge abutments and retaining walls

- Bedding, protection and insulation of water, sewer, oil & gas pipes

Applications of Foam Glass Gravel